ALTUM applies patented vacuum technology to simulate thermal effects without heat—boosting polyphenols, oleocanthal, and yield while preserving antioxidant properties.

Application:

The BSTM ALTUM Vacuum Malaxation Unit enhances the breakdown of olive cells and enzymatic activity through high vacuum technology applied via our patented automatic systems. As a result, increases of up to:

- 10% in oil yield,- 30% in polyphenol content,- 60% in oleocanthal levelshave been achieved.

Thanks to its double-jacketed design, the temperature of the olive paste can be kept at the desired level throughout the process.

Advantages:

- The double-jacketed design allows the paste to maintain the target temperature.- Easy-to-clean structure.- Significant gains in oil ratio and phenolic content through easily applicable high vacuum technology.- The horizontal design with no dead zones ensures all olive cells come into contact with vacuum.

Design:

In the BSTM ALTUM Malaxation Unit, a horizontal body is preferred to ensure that all olive cells are exposed to vacuum. Since vertical malaxers only allow vacuum to function effectively in the upper layers, this design was deliberately avoided.

The horizontal body with no dead zones ensures full and consistent vacuum contact with all olive material.

This structure also simplifies cleaning operations. Each malaxer unit is equipped with one motor responsible for mixing the olive paste. BSTM ALTUM Malaxation Units are designed to operate under high vacuum and are covered by a patent registered in our company’s name.

All surfaces in contact with olive paste are made of stainless steel.

Working Principle:

Under high vacuum and with special blade design, high oil and polyphenol yield is achieved.

Thanks to the automation system, the high vacuum technology can be operated automatically.

It simulates the effect of 60°C on olive cells at only 22°C, by creating a pressure difference between the inside and outside of the cells. This ruptures more cell membranes and increases both yield and polyphenol transfer into the oil.

Volatile compounds begin evaporating at 22°C and are fully lost by 35°C.

BSTM ALTUM Malaxers optimize this process, simplify complexity, and provide a user-friendly solution.

FAQ – Frequently Asked Questions

1. What is a vacuum malaxer and how does it improve olive oil quality?

A vacuum malaxer is an advanced mixing unit used in olive oil extraction. It enhances oil quality by preserving aroma compounds and increasing polyphenol and oleocanthal content through low-temperature, high-vacuum processing.

2. How does the BSTM Altum Vacuum Malaxer increase polyphenols in olive oil?

Thanks to patented vacuum technology, cell membranes rupture more efficiently, releasing up to 30% more polyphenols and 60% more oleocanthal compared to standard malaxation.

3. What makes the Altum Malaxer better than traditional malaxers?

Its horizontal, dead-zone-free design ensures even mixing, easy cleaning, and effective vacuum distribution — unlike vertical systems that only affect upper layers.

4. Does vacuum malaxation work at cold extraction temperatures?

Yes. The process operates at 22°C but mimics higher thermal efficiency due to pressure differentials. This keeps the process within cold extraction standards while maximizing yield.

5. Is the Altum Malaxer easy to clean and maintain?

Yes. The horizontal design with stainless steel contact surfaces allows for quick and hygienic cleaning using standard CIP methods.

6. Can the Altum Malaxer be integrated into existing olive oil production lines?

Absolutely. The unit is designed to be modular and compatible with modern extraction systems, supporting automation and line synchronization.

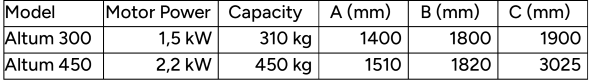

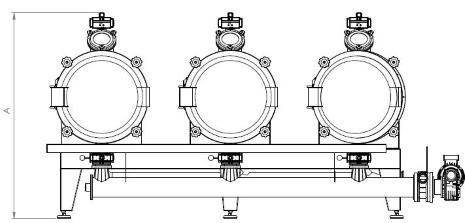

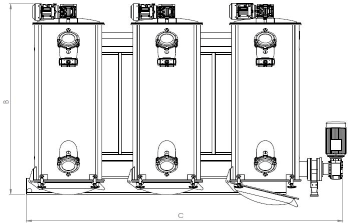

Technical Drawings

Technical Specifications