KLARA is designed to hygienically clean olives before processing, ensuring the removal of soil and leaves while preserving the integrity of the fruit—leading to longer shelf life and higher oil quality.

Application

In olive oil production, thorough cleaning of olives is crucial to obtain high quality oil. The unit effectively separates branches and leaves that may mix with olives on the line.

Olives free from dust and foreign matter yield oil that is longer-lasting and more flavorful.

Benefits

- Utilizes a powerful fan to create air bubbles in the washing water, ensuring comprehensive cleaning of olive surfaces.- The water in the tank is filtered during circulation, minimizing water usage and promoting environmental friendliness.- Gentle washing process preserves the integrity of the olives.- The wire design in the feeding hopper maximizes safety.- As olives are transported on a stainless steel wire belt, an integrated drying system removes residual water, ensuring a water-free process.

Design

The unit comprises a feeding hopper, food-grade conveyor belt, leaf separator motor, water tank, wire belt, and supporting chassis. A robust leaf-blowing motor effectively removes leaves before olives enter the crusher. The system includes:

- Three electric motors for feeding olives onto the belt.- One electric motor for the leaf separator.- One fan motor for drying.- One fan motor for creating bubbles in the water.- One water pump for circulation.

Working Principles

Olives are first loaded into the feeding hopper. They are then conveyed via a screw to an elevator conveyor belt, pass through the leaf separator, and enter the washing tank. A motor generates bubbles in the tank to ensure complete contact between olives and water. The mixture of water and olives continues along the line with the help of a pump. As olives are transported on a stainless steel wire belt towards the crusher, an integrated drying system removes residual water. This step is crucial to prevent the loss of valuable polyphenols, which are water-soluble and can be discarded with the pomace if not properly managed.

FAQ - Frequently Asked Questions

1. What is an olive washing unit and why is it essential in olive oil production?

An olive washing unit removes dirt, leaves, and foreign particles from harvested olives before crushing. This step is crucial for maintaining oil quality and avoiding contamination during extraction.

2. How does the KLARA Olive Washing Unit ensure thorough cleaning?

The KLARA unit uses a water-based cleaning system with high-efficiency nozzles and a vibrating screen or air blower (depending on model). This ensures the olives are fully cleaned without damaging their surface.

3. Is the KLARA unit suitable for continuous olive oil production lines?

Yes. The KLARA washing unit is designed for high-throughput and can be seamlessly integrated into continuous or semi-continuous olive oil extraction lines.

4. What capacity options are available in the KLARA series?

KLARA washing units are available in different sizes, typically ranging from 750 kg/hour to 2000 kg/hour, depending on the model and system configuration.

5. Is the unit made of food-grade materials?

Absolutely. All components in contact with olives and water are made from stainless steel or food-safe polymer materials to ensure hygiene and long-term durability.

6. How easy is it to maintain the KLARA washing unit?

The KLARA series is built for easy maintenance with accessible components, quick-clean filters, and optional self-cleaning systems to minimize downtime.

7. Can this unit be integrated into all olive oil production systems?

Yes. This unit is compatible with most modern and traditional olive oil production setups and can be combined with crushers, malaxers, and decanters.

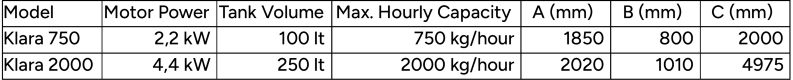

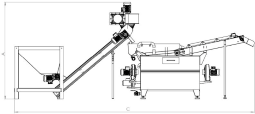

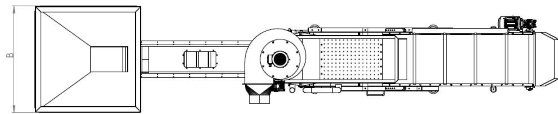

Technical Drawings

Technical Specifications