BSTM presents a two-phase decanter specifically designed for extra virgin olive oil production. This unit delivers maximum yield, aroma, and polyphenol content—while maintaining stable temperatures and operating without any heat increase during extraction.

Application:

The ANTA Decanter Unit, developed by BSTM engineers, performs the phase separation in olive paste without applying additional water or mechanical stress. The system is designed to preserve the natural composition of the oil and minimize quality loss.

Advantages:

- Two-phase separation with no added water- Preserves oil quality and phenolic compounds- High capacity and continuous operation compatibility- Easy to maintain and clean- Energy-efficient high-speed separation

Design:

The decanter unit includes a horizontal cylindrical bowl and a conical screw conveyor rotating at differential speeds.

The high-speed rotating bowl creates centrifugal force that pushes the heavier solid olive pomace outward, while the lighter oil collects closer to the center.

Thanks to the optimized conical screw conveyor, solids are discharged with minimal moisture, keeping more oil in the liquid phase.

An electronic control panel allows real-time adjustment of speed differences between the bowl and the screw.

Operating Principle:

Olive paste is fed into the decanter bowl, which spins at high speed to generate centrifugal force. This separates the mixture into:

- Oil (lighter phase)- Olive pomace (heavier phase)

Since no water is added during the process, phenolic content is better preserved, and waste generation is minimized.

FAQ - Frequently Asked Questions

1. What is an olive oil decanter and how does it work?

An olive oil decanter is a horizontal centrifuge that separates olive oil from water and solids in the paste. It works based on high-speed rotation and density differences to achieve three-phase or two-phase separation.

2. What makes the ANTA Decanter different from other olive oil separators?

The ANTA Decanter features high-speed continuous operation, minimal oil loss, and easy cleaning. Its design ensures efficient separation even with variable olive paste conditions.

3. Is the ANTA Decanter suitable for cold-pressed olive oil production?

Yes, the ANTA Decanter is fully compatible with cold extraction systems and operates efficiently at low processing temperatures to preserve the oil’s nutritional and sensory qualities.

4. What is the capacity range of the ANTA olive oil decanter?

ANTA Decanters are available in various capacity options, typically ranging from small-scale artisan setups to industrial-scale production. (Optional: You can specify exact models and capacities here.)

5. How easy is it to clean and maintain the ANTA Decanter?

The unit is designed for easy disassembly and includes CIP (Clean-in-Place) compatibility. Its stainless steel components resist corrosion and allow for hygienic operation.

6. Can the decanter be integrated into automated olive oil processing lines?

Absolutely. The ANTA Decanter supports integration with automated systems including malaxers, pumps, and separation modules, enabling streamlined and continuous operation.

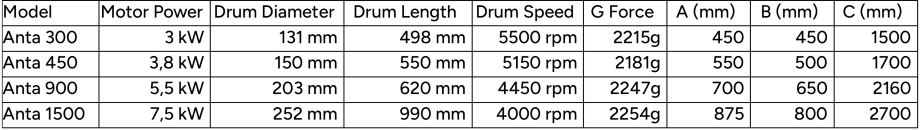

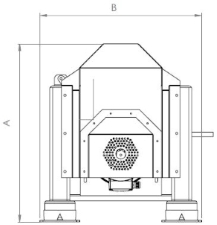

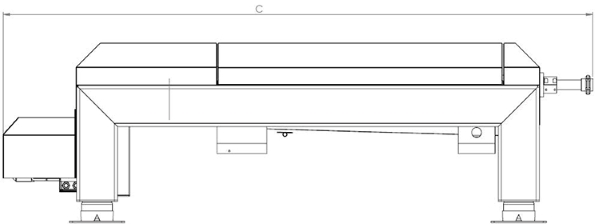

Technical Drawings

Technical Specifications