KRUSA crusher efficiently breaks olives into paste with customizable sieve and blade options—maximizing oil yield and phenolic content without overheating the cells.

BSTM manufactures the following crushers tailored to different needs:

- Knife Crusher- Crusher with Pit Separator

Different sieve options are available for various olive varieties and harvest periods (early, mid, and late):

- 5 mm

- 6 mm

- 7 mm

Application

Paste preparation is a critical stage that directly affects both the quality and yield of olive oil. Breaking the olive cell membranes without generating excess heat has a significant impact on the aroma and polyphenol content of the oil. This is also when enzymatic activity, particularly involving lipoxygenase (LOX), begins.

Benefits

- High yield- High phenolic compound retention- High aroma efficiency- Optimal operating temperatures- Sieve options for different olive types- Interchangeable hammer / knife / pin crushing heads

Design

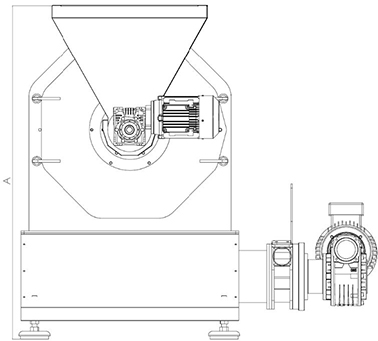

BSTM crushers and pit separators are designed in a modular structure on a single chassis. This modularity allows users to switch between different crushing technologies based on the olive type, making it possible to prepare the most suitable paste.

The unit includes three motors:

- One motor for the crushing mechanism- One motor for the scraper mechanism- One motor (with adjustable speed) for feeding the crusher

Thanks to the easily interchangeable hammer, knife, and pin heads, along with various sieve options, the unit offers flexibility for different olive varieties and harvest stages.

Working Principles

Crushing Unit: Olives are fed into the crusher via a screw conveyor. Rotating blades break the olives and push the paste through the fixed sieve holes using a hammer mechanism. The thickness and texture of the resulting paste can be adjusted using different sieve sizes.

Cooling System: BSTM’s specially designed cooling system allows users to control the desired temperature during crushing. Since temperature is a key factor affecting olive oil quality, this system gives the operator full control over processing conditions.

FAQ - Frequently Asked Questions

1. What is an olive crusher and what is its role in olive oil production?

An olive crusher breaks down the olive fruit, including the flesh and pit, into a fine paste. This paste is then processed in the malaxer to extract the oil. It is the first critical step in the extraction process.

2. How does the KRUSA Olive Crusher differ from other crushing systems?

The KRUSA series features a knife-based crushing system that ensures uniform paste consistency while minimizing heat generation. This preserves the integrity of aromas and phenolic compounds.

3. Is the KRUSA crusher suitable for cold-pressed olive oil production?

Yes. Thanks to its low-shear, low-temperature design, the KRUSA crusher supports cold extraction by preserving heat-sensitive nutrients and flavors in the paste.

4. What is the capacity range of the KRUSA crusher models?

The KRUSA series offers various capacity options, commonly ranging between 750 kg/h and 2000 kg/h, depending on the model configuration and processing line requirements.

5. Can the crusher handle olives with pits or should they be removed beforehand?

The KRUSA Olive Crusher is designed to process whole olives, including the pits. However, optional configurations for pit removal (destoning) are available if needed for specific oil profiles.

6. How easy is it to clean and maintain the KRUSA unit?

It features an accessible interior design with stainless steel construction, making it easy to clean and maintain. Quick access panels simplify daily maintenance routines.

7. Can this unit be integrated into all olive oil production systems?

Yes. The KRUSA Olive Crusher is fully compatible with both traditional and modern production lines and integrates seamlessly with malaxers, washing units, and decanters.

Technical Drawings

Technical Specifications