MALASA malaxer kneads olive paste under precise temperature control to optimize enzyme activity, improve aroma release, and ensure stable oil quality in traditional olive oil production.

Application

The malaxation stage plays a critical role in both the quantity and quality of olive oil produced. The kneading time, blade design, and temperature combination are essential for releasing oil and aroma. Proper temperature, adequate oxygen, and optimal mixing duration determine the quality of the oil and facilitate the decanter’s operation. Thanks to its double-jacketed design, the tank maintains the paste at the desired temperature throughout the process.

Benefits

- Double-jacketed structure enables precise paste temperature control- Made from long-lasting, wear-resistant materials- Easy-to-clean design- Inspection windows allow real-time process monitoring

Design

Innovations in the design of blades and mixing paddles allow for more effective cell rupture, increasing oil yield, aroma intensity, and polyphenol content. Each malaxer tank is equipped with a dedicated motor that drives the mixing mechanism.

Operating Principle

The malaxation phase involves gently mixing the olive paste at a controlled, constant temperature. This process breaks cell membranes, allowing microscopic oil droplets to coalesce. With specially designed mixing paddles and blades, more oil droplets are united and a higher percentage of antioxidants are transferred into the oil. As a result, higher-quality oil is obtained compared to conventional systems.

Once the mixing process is complete, the olive paste is transferred to the decanter by a paste pump for phase separation.

FAQ - Frequently Asked Questions

1. What is an olive malaxer and why is it important in olive oil production?

An olive malaxer is a mixing chamber where the olive paste is slowly stirred at a controlled temperature. This process helps oil droplets merge, enhancing extraction efficiency and final oil quality.

2. How does the MALASA Malaxer improve olive oil quality?

The MALASA Malaxer offers controlled temperature management and gentle mixing, which improves oil yield, maintains low oxidation levels, and preserves volatile aroma compounds.

3. Is the MALASA Malaxer suitable for cold-pressed olive oil?

Yes, the MALASA series is designed to meet cold extraction requirements. It keeps the paste temperature below 27°C to ensure nutritional and sensory values are preserved.

4. What sizes or capacities are available in the MALASA series?

The MALASA series includes malaxers in various capacities suitable for small producers to industrial-scale operations. Specific tank sizes and hourly capacities can be tailored upon request.

5. How is cleaning performed in the MALASA Malaxer?

The MALASA is engineered for easy cleaning with stainless steel surfaces and smooth internal walls. It supports CIP (Clean-in-Place) systems for efficient maintenance.

6. Can the MALASA Malaxer be used with automated olive oil processing lines?

Absolutely. The MALASA Malaxer is compatible with automated setups, including connection to crushers, pumps, and decanters for a seamless production flow.

7. Can this unit be integrated into all olive oil production systems?

Yes. This unit is designed to be compatible with a wide range of traditional and modern olive oil production lines. It can be seamlessly integrated with crushers, malaxers, decanters, and other modular units for efficient operation.

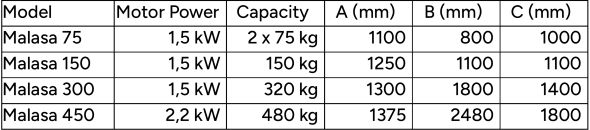

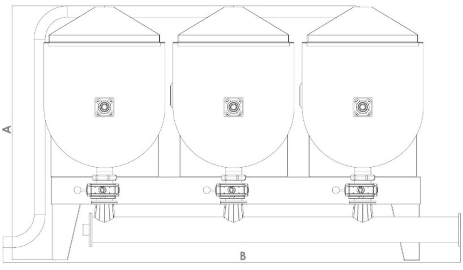

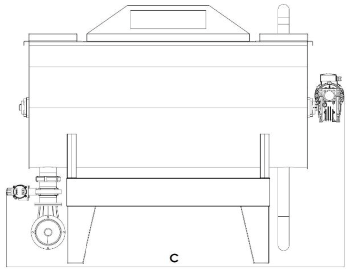

Technical Drawings

Technical Specifications