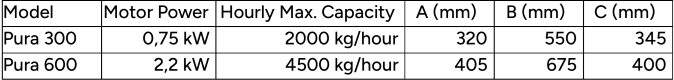

BSTM’s food-grade olive paste pumps ensure gentle and continuous transfer between processing units—minimizing paste damage, air exposure, and quality loss.

Application:

The pump group is used to carry the olive paste between units such as crusher, malaxer, decanter, and other connection points. These pumps allow continuous flow of paste while preserving consistency, minimizing air contact, and preventing damage.

Advantages:

- Prevents damage to olive paste structure- Designed for continuous operation- Compatible with both vertical and horizontal lines- Hygienic and easy to clean- Durable, low-maintenance construction- Various flow rate options available

Design:

All olive paste pumps are designed for food-grade use and made of AISI 304/316 stainless steel.

The flow speed and impeller geometry are optimized to ensure homogeneous, gentle paste transfer without pressure loss or cavitation.

Each pump is connected to the operating panel and the flow rate is controllable

Working Principle:

Olive paste is transferred through stainless steel pipelines using positive displacement or rotor-driven pumping methods.

The pump’s geometry ensures consistent paste flow, minimizes temperature rise, and avoids shear damage—helping to maintain the oil’s aroma and antioxidant integrity.

Frequently Asked Questions - FAQ:

1. What is an olive paste pump and why is it important in olive oil production?

An olive paste pump is a specialized industrial pump designed to transfer crushed olive paste between processing units. It ensures smooth, hygienic, and continuous flow from crushers to malaxers and from malaxers to decanters, maintaining process efficiency and product quality.

2. Can olive paste pumps handle viscous and fibrous materials?

Yes. Olive paste pumps, especially those with elliptical rotors, are engineered to handle high-viscosity and fiber-rich materials without clogging or overheating. This makes them ideal for thick olive paste transfer.

3. Are BSTM olive paste pumps suitable for continuous production lines?

Absolutely. BSTM paste pumps are designed for seamless integration into continuous olive oil processing systems, ensuring uninterrupted flow and reducing downtime.

4. Do the pumps require frequent maintenance?

No. Thanks to their wear-resistant construction and stainless steel contact surfaces, BSTM pumps require minimal maintenance and are easy to clean using CIP (Clean-in-Place) procedures.

5. Is there a risk of aroma loss due to heat generation during pumping?

Not with BSTM pumps. The low-friction elliptical rotor design minimizes heat buildup, helping to preserve the olive oil’s aroma and phenolic profile.

6. Can I request custom capacities or design features?

Yes. We offer customized designs based on your production volume and specific material characteristics. Contact us for tailored solutions.

7. Can this unit be integrated into all olive oil production systems?

Yes. Our olive paste pumps are compatible with a wide range of traditional and modern production lines, including modular systems with crushers, malaxers, decanters, and storage tanks.

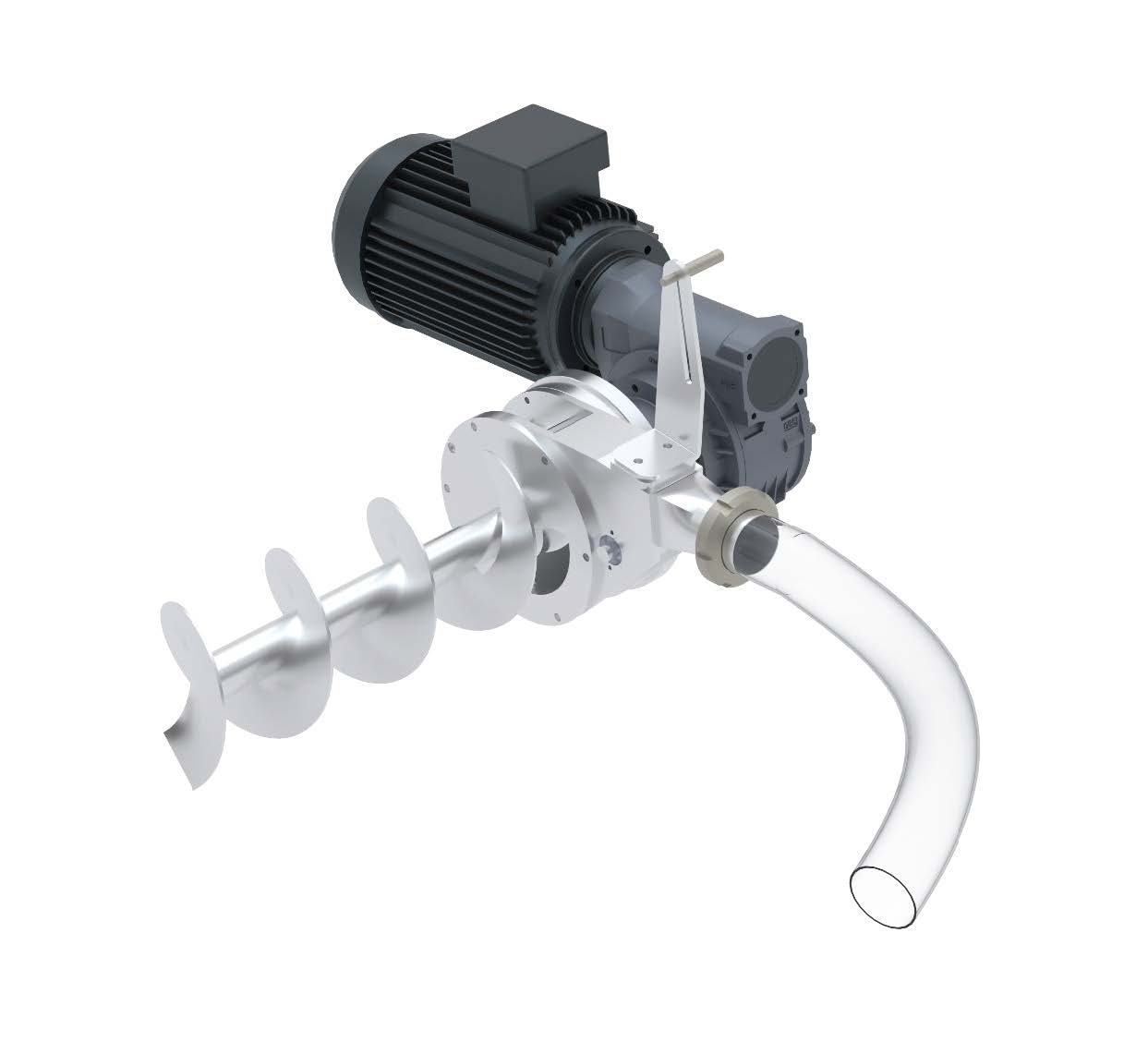

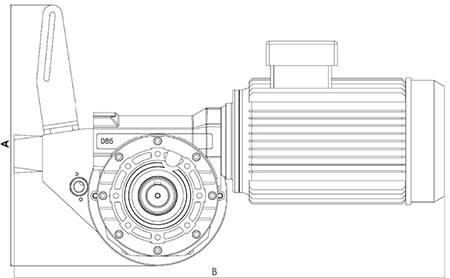

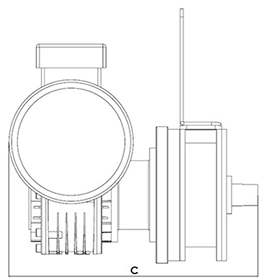

Technical Drawings

Technical Specifications