BSTM’s pomace pumps are engineered for the reliable transfer of dense, fibrous olive waste—offering uninterrupted flow from decanter to disposal.

Application:

After oil extraction in the decanter, the remaining solid material called pomace must be transported hygienically and efficiently.

BSTM pomace pumps ensure continuous flow of pomace from the decanter outlet to the designated waste collection or drying unit.

Advantages:

- High-torque design suitable for dense and fibrous material- Continuous operation with high durability- Stainless steel or carbon steel body options- Low maintenance and clog-resistant construction- Compatible with horizontal or inclined lines- Can be used with conveyors or screw systems

Design:

The pump body and screw are built for heavy-duty applications.

Various models are available based on flow rate, installation angle, and output height.

The system is optimized to prevent clogging while ensuring the safe and hygienic transport of olive pomace.

Optional screw conveyors or discharge chutes can be integrated depending on the layout.

Working Principle:

Pomace is pushed through a cylindrical body using a powerful screw or progressive cavity system.

The mechanical configuration prevents material buildup and ensures the smooth evacuation of the decanter’s solid output.

Frequently Asked Questions - FAQ:

1. What is an olive pomace pump and what is its role in olive oil production?

An olive pomace pump is an industrial pumping system used to transfer solid waste (pomace) from the decanter to waste management or processing units. It ensures efficient handling of byproducts like olive pulp after oil extraction.

2. Can the pomace pump handle dense and abrasive materials?

Yes. BSTM olive pomace pumps are built from wear-resistant materials to handle high-viscosity and abrasive pomace. Their robust design allows them to operate continuously without performance loss.

3. Is the pump compatible with all olive oil production systems?

Absolutely. Our pomace pumps are designed to integrate seamlessly with any modular or continuous olive oil processing line, regardless of size or layout.

4. How is the pump cleaned and maintained?

The pump features an easy-access design that allows quick disassembly and cleaning. Stainless steel contact surfaces ensure hygiene and prevent corrosion, especially in high-moisture environments.

5. Is the flow rate adjustable?

Yes. The pump operates with a speed-controlled motor, allowing producers to adjust flow according to production needs and system capacity.

6. Can the pump be used outside olive oil production?

Yes. In addition to olive oil factories, these pumps are also used in biogas plants, organic fertilizer transfer systems, and other agricultural waste management applications.

7. Can this unit be integrated into all olive oil production systems?

Yes. It is fully compatible with crushers, malaxers, decanters, and storage systems across traditional and modern olive oil production setups.

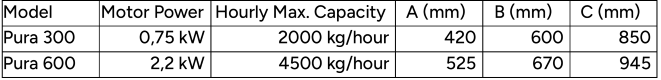

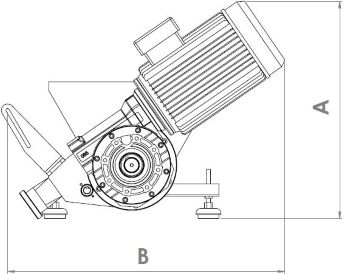

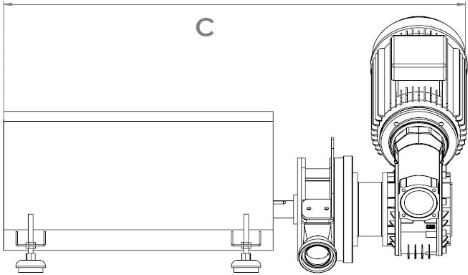

Technical Drawings

Technical Specifications